External Conditions and Subsequent Processing Factors

Even when produced micro silica exhibits high inherent activity, subsequent processing and usage conditions can significantly impact its ultimately manifested activity.

Agglomeration Effect

Impact: Due to the extremely fine particle size and high surface energy of micro silica, particles strongly attract each other via van der Waals forces, forming loose agglomerates.

Mechanism: These agglomerates “envelop” portions of the micro silica, preventing effective dispersion and contact with cement particles, thereby significantly reducing its effective reactivity. Breaking agglomerates is a critical step in unlocking its reactivity.

Curing Conditions (Temperature and Humidity)

Impact: The pozzolanic reaction is a chemical process highly sensitive to temperature and humidity.

Temperature: Elevating curing temperatures (e.g., steam curing) significantly accelerates the pozzolanic reaction rate, enabling full early-stage utilization of micro silica’s activity.

Humidity: Sufficient humidity must be maintained to provide a continuous water supply for hydration and pozzolanic reactions. Dry conditions halt these reactions.

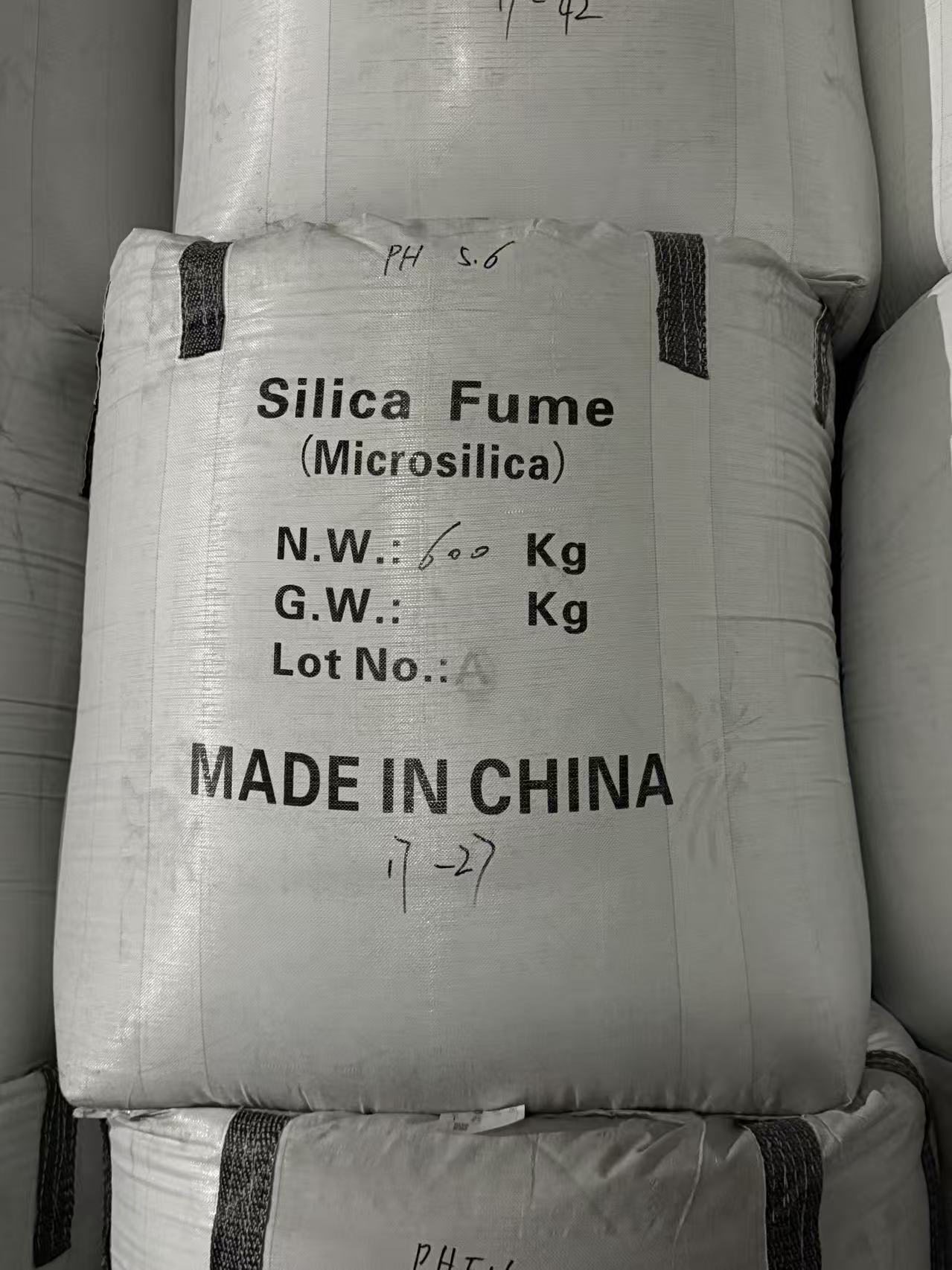

Alkaline Environment (pH)

Impact: The pozzolanic reaction requires an alkaline environment.

Mechanism: Cement hydration produces Ca(OH)₂, raising the pore solution pH to 12-13. This highly alkaline environment dissolves the amorphous SiO₂ protective layer on the micro silica surface, activating its reactivity. This enables further reaction with Ca(OH)₂ to form additional C-S-H gel.

Density and Mixing Process

Impact: Thorough mechanical mixing or using high-efficiency water-reducing agents helps break up micro silica agglomerates for uniform distribution within the cement matrix.

Mechanism: Proper dispersion ensures each micro silica particle participates in physical and chemical reactions; otherwise, its reactivity is wasted.

Common “Negative” Factors Reducing Reactivity

Excessive Carbon Content: Derived from incompletely burned coke during smelting. Carbon particles themselves are inactive, adsorb air-entraining agents and water-reducing agents, and hinder MSF bonding with cement paste, reducing activity.

Partial Crystallization: If MSF undergoes prolonged high temperatures during collection, storage, or transportation, amorphous SiO₂ may transform into crystalline forms like quartz, causing permanent loss of activity.

Improper Storage and Moisture Exposure: Moisture absorption causes pre-hydration on the surface of micro silica particles, forming a gel layer that coats the particles. This delays or reduces their reactivity during subsequent use. Additionally, damp micro silica is more prone to forming hard agglomerates, making dispersion difficult.